What is beam to beam connection in steel structure

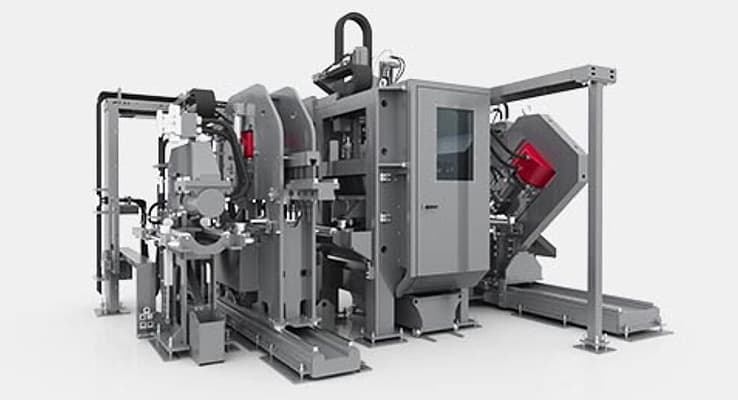

Beam Layout Welding offers easy access diagnostics indicators as well message display and custom graphics. These include electrical, hydraulic, and functional schematics. Keyboard or touch screen input is possible.